Parts & Maintenance Contract

Generator Set

About Us

PCMGE was born from the partnership of Laure PARADIS and Frédéric CHARRON.

After several years of collaboration with a manufacturer and designer of generator sets, we have acquired recognized expertise and technical skills in the field of backup energy provided by generator sets and/or UPS.

We are present with companies and individuals for all maintenance contracts, repair work, engine overhaul nationwide, and for the sale of multi-brand spare parts, Original and Export.

PCMGE advises you on bringing your installed equipment into compliance and assists you during your safety commissions to obtain approvals for your backup installations.

PCMGE is here to support you in sustaining your installations as best as possible.

Services

SALES & INSTALLATION

- Sale of generator sets from 15 to 1500 KVA

- Study, monitoring, and turnkey installation

- Tailor-made solutions according to your needs

- Products from the largest manufacturers

MAINTENANCE

4 TYPES OF CONTRACTS:

- Maintenance Contract

- Load Test Contract

- On-call Contract

- Load Bank Contract

SERVICES

- Training in the use and maintenance of generator sets

- Commissioning, connection, testing, troubleshooting

- Assistance with safety commissions

OUR 4 MAINTENANCE CONTRACTS

Maintenance Contract

Recommendation of 2 visits per year; 1 electrical and 1 mechanical.

Any malfunction or anomaly detected by the technician and not requiring spare parts is corrected during visits.

Load Test Contract

The technician visits the client's site monthly to carry out load tests on the generator set during EDF network outages.

Production readings are taken and sent to the client.

On-call Contract

An on-call service is available 24/7 for clients who wish to subscribe.

Its purpose is to ensure troubleshooting in case of generator set failure to start.

Load Bank Contract

This contract aims to allow full-load operation of generator sets that have lost their full power.

The operating time varies between 4 and 8 hours.

OUR WORKS

Controller modernization

Their purpose is to address the obsolescence of the generator set and enable remote management.

Controller replacement allows clients to have technical data and immediate feedback on faults and anomalies.

Engine overhaul

On the engine manufacturer's recommendation and depending on the machine's operating hours:

- Replacement and/or adjustment of injectors

- Endoscopy

- Rocker adjustment

- Cylinder head replacement

- Replacement of water pump and thermostats

- Adjustment of alternator voltages and frequency

- Replacement of suspension mounts

- Radiator descaling and coolant replacement

Replacement of wear parts

- Starter batteries

- Starter – Alternator

- Engine sensors and heaters

- Belts

- Voltage and speed regulators

Our Suppliers

We offer you multi-brand spare parts, Original and Export.

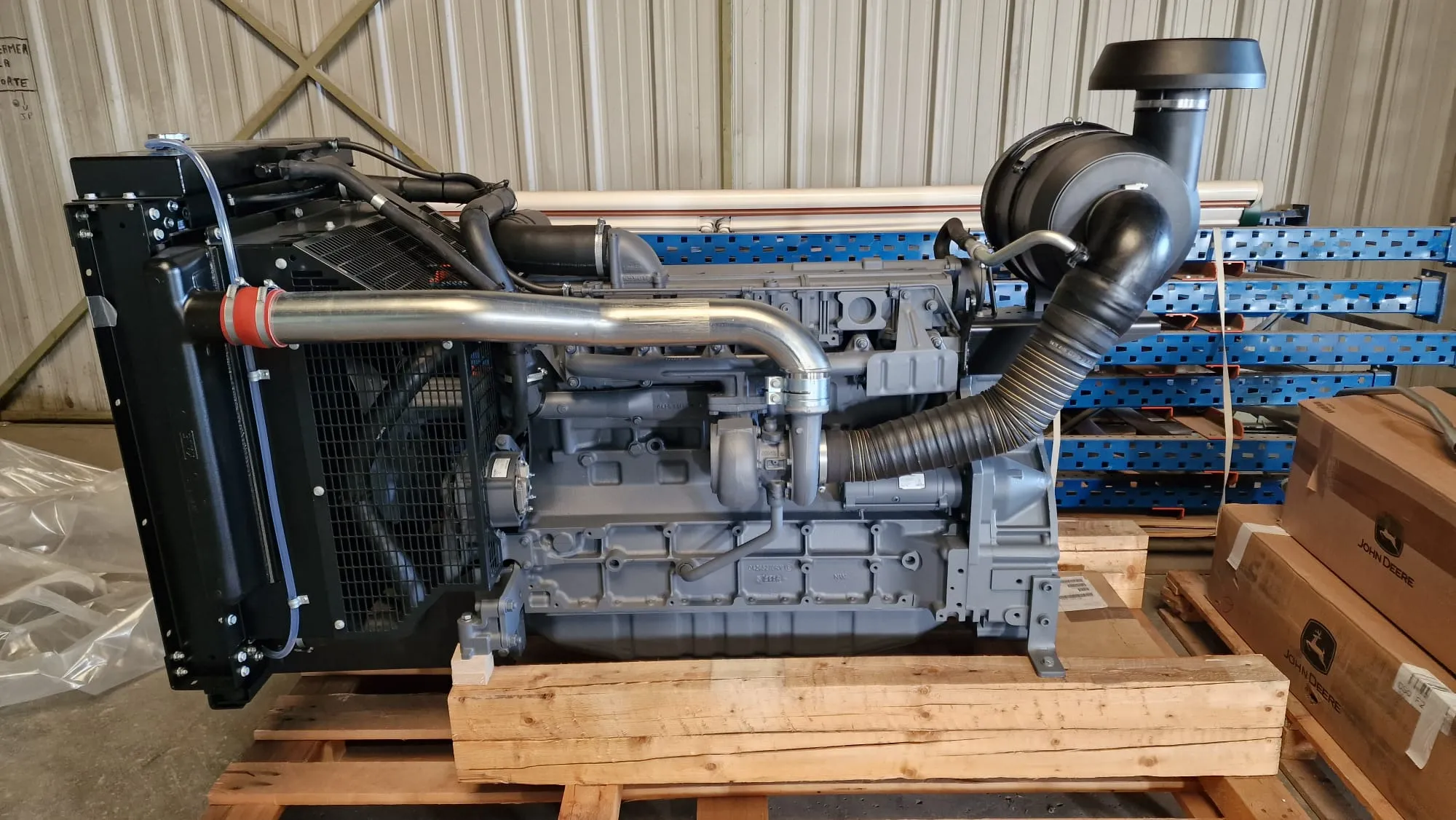

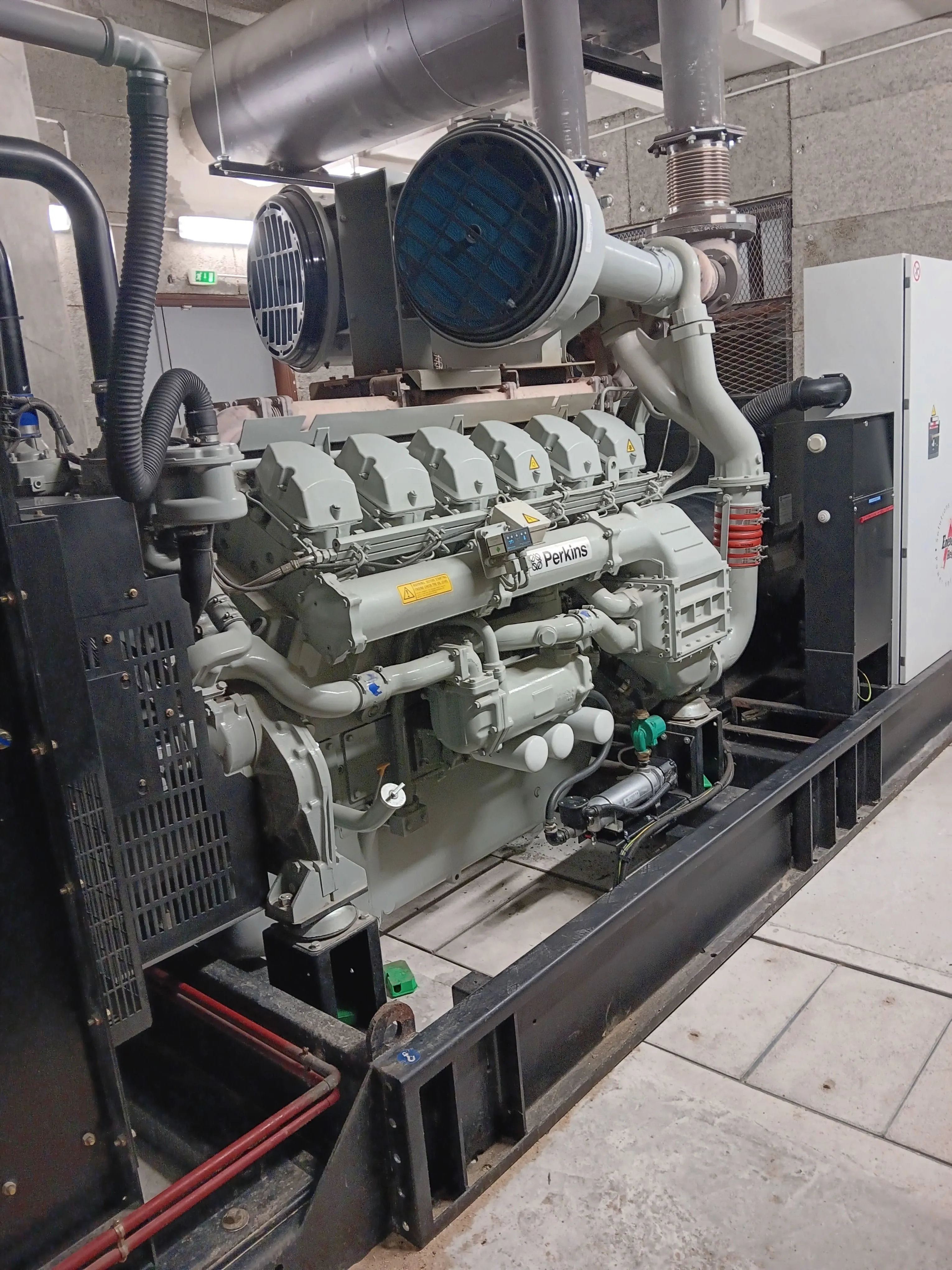

Photo Gallery

Testimonial

PCMGE supports cardiovascular research

In May 2025, PCMGE supported the 'Défi de l’Espoir', a solidarity initiative for the French Federation of Cardiology. This cycling challenge aims to raise awareness of cardiovascular health and collect funds for research.

This partnership reflects PCMGE's values: solidarity, health prevention, and social responsibility.

See the Facebook postFrequently Asked Questions

-

1 - Why should I service my generator?

We recommend a general check, adjustment, and tests every 2-3 months.

A general service and oil change should be performed once a year even if the operating time is not reached.

Additionally, you should test your generator once a month for 10 to 15 minutes.

The maintenance of your generator must be carried out by a qualified technician. -

2 - What happens if my generator runs underloaded?

It is harmful to use the generator at low load.

Such use will shorten the engine's lifespan and cause significant damage.

The minimum recommended load for backup generators is 30% of total load.

Problems that may occur when running at no load or low load include:

- Accumulation of soot in cylinder head covers or exhaust manifolds due to unburned fuel residues.

- Loss of sealing at engine joints

- White exhaust smoke -

3 - What should I do if I don't use my generator for a long period?

Generators should be tested at least once a month without load for 10 minutes or until the engine temperature reaches around 80°C (the correct operating temperature for a combustion engine).

Starting your generator monthly will circulate engine oil to all internal components, ensuring lubrication.

This monthly operation also slightly recharges the starter batteries. -

4 - What happens if I overload my generator?

Overloading your generator can cause the following problems:

- Engine overheating

- Increased engine wear

- Overheating of alternator windings

- Reduced engine lifespan -

5 - Why should I replace my coolant every 2 years?

Coolant is essential for the proper functioning of your generator.

In addition to ensuring good engine cooling, this fluid has antifreeze properties.

Not replacing your coolant exposes you to overheating problems during summer.

Its antifreeze concentration also decreases over time.

If this concentration drops too much, the fluid can freeze in winter, increasing its volume and causing damage to your pipes and radiator.

PCMGE

PCMGE